Inventory Management

WATCH THE VIDEO

The delivering plant refers to the plant from which the goods are to be delivered to the customer, within a specific sales organization and distribution channel. The delivering plant is also used to calculate inventory. It can contain one or more storage locations. The plant can be automatically proposed by the system when processing a sales order, if it has been maintained in one of the master records or a webstore. It can be derived from:

- Web store (the Webstore Configuration window)

- Customer / product info record

- Customer master record of the ship-to party

- Material master record

Which delivering plant should be used to calculate inventory is defined according to priority as in the list above.

From this article you will learn how to set up delivering plants and storage locations for a Sana webstore. If you configure delivering plants and storage locations for your Sana webstore, they will be used to calculate inventory, and those configured for customers and materials will be ignored.

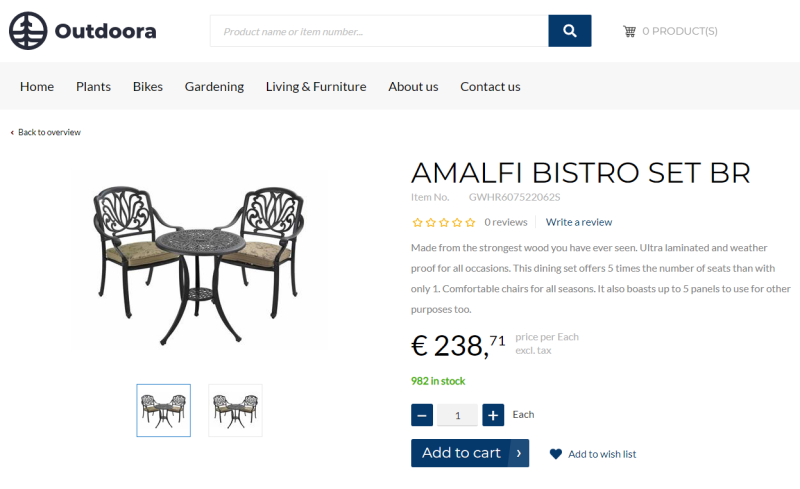

Stock is shown in a Sana webstore on all product pages. This can be a simple text, a stock indicator of different colors, or a stock amount. Stock amount is retrieved from and calculated by SAP real-time. Thus, when customers place orders from a Sana webstore, stock is automatically adjusted by SAP.

Storage Locations

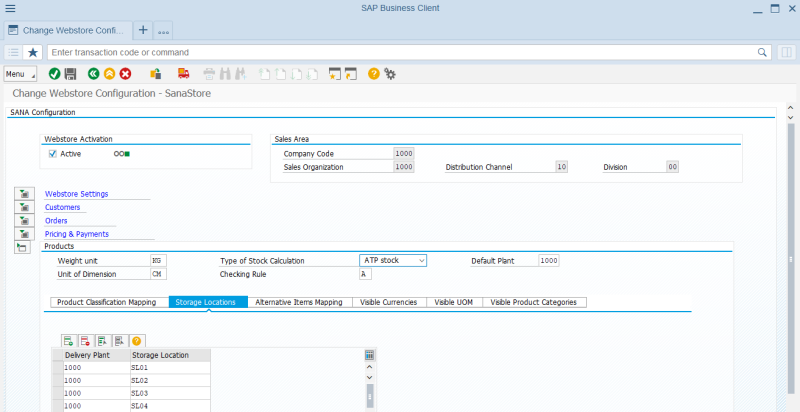

In SAP use the Storage Locations table to set up the delivering plant and storage location for a webstore.

Step 1: In the main menu of the Sana add-on, click Webstore Configuration.

Step 2: In the Webstore Id field, select your webstore and click on the Change Webstore Settings button at the top.

Step 3: Expand the Products area.

Step 4: Use the Storage Locations table to set up the delivering plants and storage locations for the Sana webstore.

The table below provides the description of the fields in the Storage Location table.

| Field | Description |

|---|---|

| Delivery Plant | Select the plant and storage location which should be used to calculate stock for the catalog. You can set up one storage location for the webstore or you can add multiple records for the webstore and define several storage locations for a single webstore. If you add multiple storage locations for the webstore, total stock will be calculated based on all storage locations and shown in the webstore. |

| Storage Location |

Delivering Plant

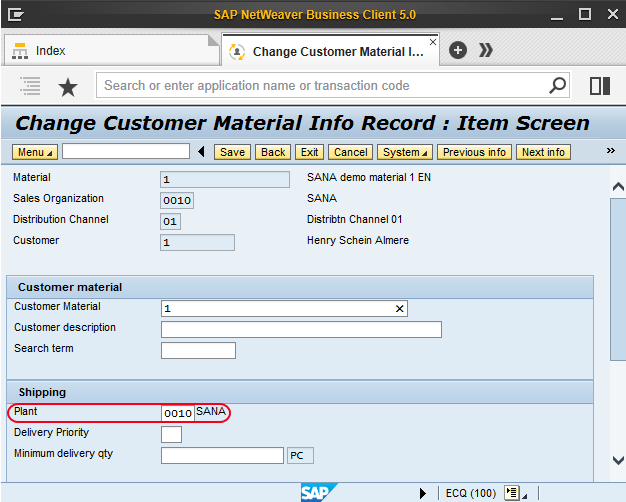

To configure the delivering plant, in the Customer Material Info Record use the following transaction codes:

- Create Customer-Material Info Record (VD51)

- Change Customer-Material Info Record (VD52)

- Display Customer-Material Info Record (VD53)

You can set the plant in the Shipping area of the Customer Material Info Record.

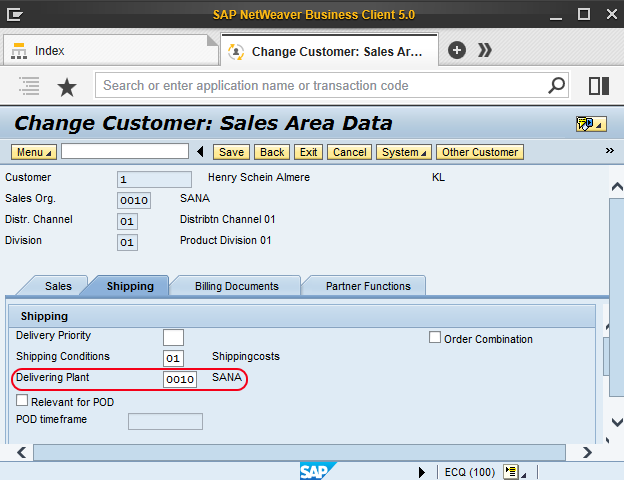

Use the following transaction codes to set the plant in the Customer master record:

- Create Customer (XD01)

- Change Customer (XD02)

- Display Customer (XD03)

Open Sales area data and on the Shipping tab, choose the delivering plant.

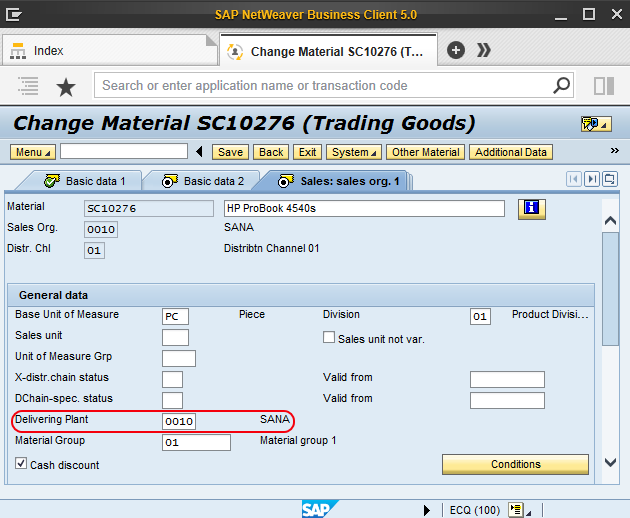

Use the following transaction codes to define the delivering plant in the Material master record:

- Create Material (MM01)

- Change Material (MM02)

- Display Material (MM03)

On the Sales organization 1 tab, set the delivering plant.

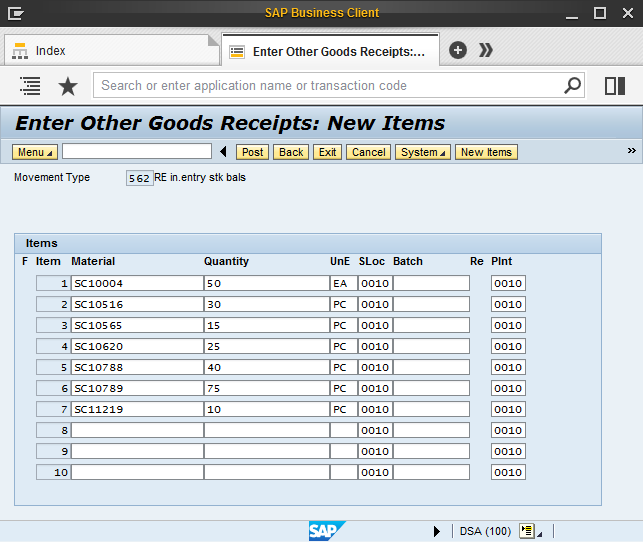

Using transaction Other Goods Receipts (MB1C) in SAP, you can manage stock amount per plant and storage location.

Inventory

WATCH THE VIDEO

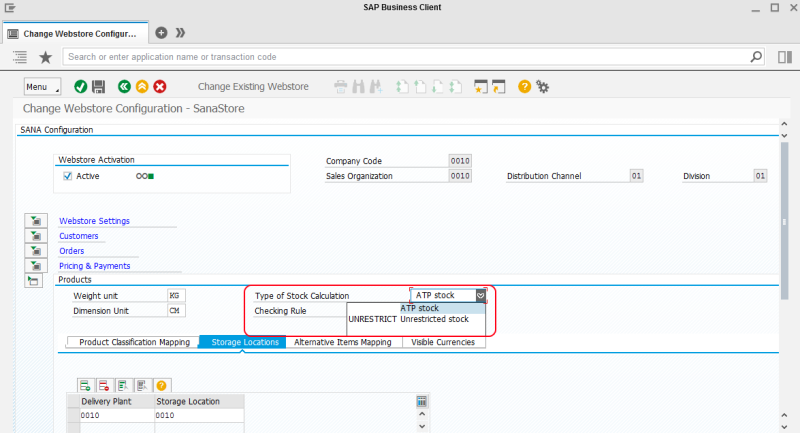

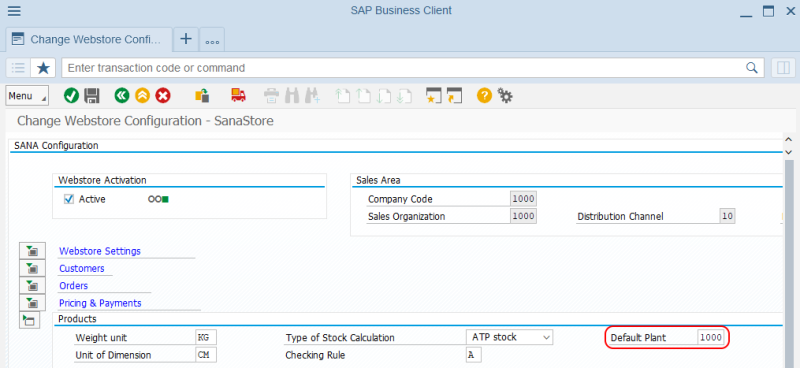

There are two types of stock calculation:

- Available-to-promise (ATP)

- Unrestricted

Step 1: In the main menu of the Sana add-on, click Webstore Configuration.

Step 2: In the Webstore Id field, select your webstore and click on the Change Webstore Settings button at the top of the window.

Step 3: Expand the Products area.

In different projects sales managers want to show product availability (stock) the way that meets the requirements of their business.

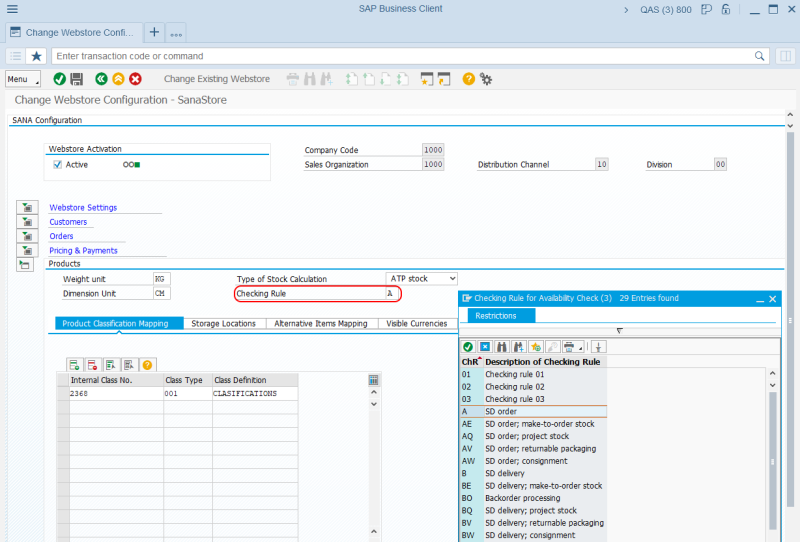

If you use ATP stock calculation type, you can select different checking rules. The checking rule defines the checking procedure for ATP stock calculation, for example which receipts should be taken into account in the availability check. The A (SD order) checking rule is used by default, if no value is set.

Using the Unrestricted stock calculation type, you can show a quantity that is physically located in the warehouse and is not subject to any usage restrictions.

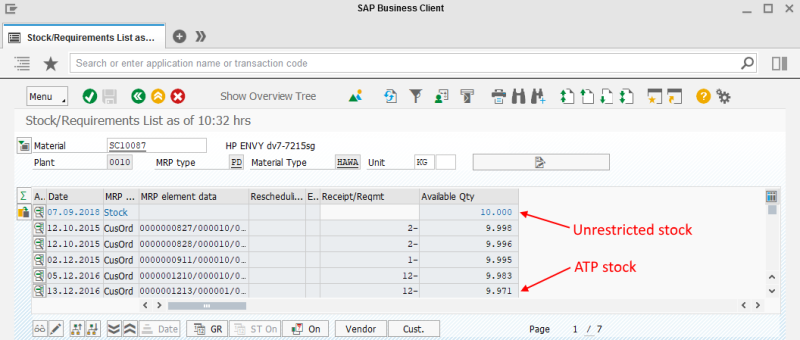

You can check stock amount using the Stock/Requirements List in SAP (MD04).

Default Plant

In the Webstore Configuration window in SAP, you can also select the default plant. This may be necessary if the material is kept in multiple plants in SAP and:

- If you retrieve plant data for the materials from the MARC table using the extra fields mapping. It is necessary to take the correct data for the selected (default) plant. Otherwise, the first available plant entry is used.

This is particularly important in SAP, as tables like MARC can contain multiple entries for the same material across different plants. Without specifying which plant to use, SAP may default to the first available entry, which can result in incorrect data being selected. By setting the default plant, the connector logic can accurately identify and retrieve the correct data, ensuring that only relevant values are sent to Sana.

- If you use the Estimated Shipment Date content element add-on. To show the estimated shipment date on the product details page for the default plant. If the default plant is not set, the estimated shipment date will be taken for the first available plant entry.

To calculate the estimated shipment date, the plant value must be passed to the relevant SAP function module. The Default Plant setting allows the webstore administrator to specify which plant should be used for this calculation. If no default plant is defined, the system will use the first available plant entry listed on the Storage Locations tab in the Webstore Configuration app, which may lead to inaccurate shipment dates being displayed.

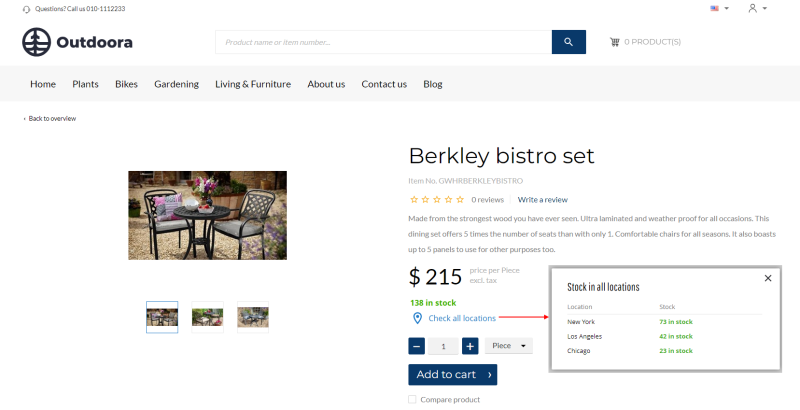

Multi-Location Stock

Read the Multi-Location Stock article for a detailed description of this feature.

Plants and Storage Locations

In SAP ECC, you can create plants and storage locations – important organizational units in inventory and logistics management.

A plant represents a location where certain business processes take place, such as production, procurement, maintenance, and materials planning.

A storage location is a part of the plant that defines the physical areas of it where materials are stored. Multiple storage locations can exist within a single plant to separate materials based on factors like their type, size, or usage.

Plants and storage locations in SAP ECC are essential for managing multi-location stock in Sana Commerce Cloud.

When you enable multi-location stock in Sana Commerce Cloud, the system checks:

- The plant assigned to the customer.

- The default plant assigned to the webstore.

- The storage locations assigned to the webstore. Only storage locations added to the Webstore Configuration app are used to display stock in the Sana webstore.

Sana Commerce Cloud relies on the storage location's address for certain features. If a storage location does not have its own address specified, SAP ECC will automatically use the address of the plant to which that storage location belongs.

Multi-Location Stock Presentation

Depending on your plants and storage locations setup in SAP ECC, the multi-location stock can be displayed on webstore pages in various ways. Below you will find all possible presentation scenarios.

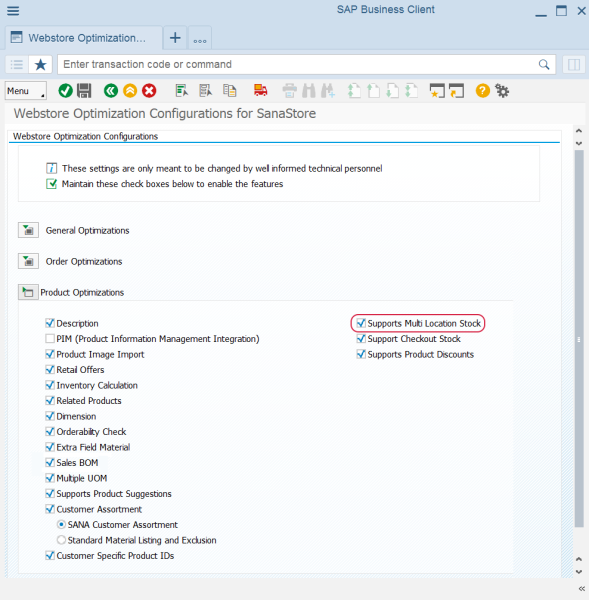

Enable or Disable Multi-Location Stock in SAP

You can enable or disable multi-location stock in SAP using the Webstore Optimization window. You can access Webstore Optimization from the main window of the Sana Commerce solution (/n/sanaecom/webstore), or by calling the transaction /n/sanaecom/optimize. To enable or disable multi-location stock, expand Product Optimizations and use the Supports Multi Location Stock checkbox. For more information, see Webstore Optimization.

Related Articles

Inventory Management

Inventory Tracking

Stock Levels

Stock Presentation

Multi-Location Stock